Carrier Weatherexpert 48N Commercial Rooftop Units: Superior HVAC Solutions for Toronto Businesses

Enhance your commercial space with the Carrier Weatherexpert 48N Commercial Rooftop Units, designed to offer unparalleled heating and cooling efficiency. As an authorized dealer of Carrier products in Toronto, Cozy Comfort Plus is your go-to source for expert installation, reliable repair services, and comprehensive product support. Serving North York and the entire Greater Toronto Area (GTA), we provide tailored HVAC solutions that cater to the unique needs of your business.

Performance Features of Carrier Weatherexpert 48N

The Carrier Weatherexpert 48N series stands out with high capacity and high efficiency models that meet or exceed the EER requirements of ASHRAE Standard 90.1. With multiple high-efficiency scroll compressors, these units offer up to 8 steps of cooling capacity control. The integrated ComfortLink™ control system allows for seamless operation and diagnostics, ensuring optimal performance in varying conditions from 32°F to 125°F.

Reliable Technology and Brand Excellence

Carrier, a leader in HVAC innovation, ensures each Weatherexpert 48N unit is equipped with dual independent refrigeration circuits for reliability and efficiency. The advanced construction includes a double wall foam panel design, providing durability and sound reduction. With a reputable standing, Cozy Comfort Plus proudly offers these robust units, backed by our BBB A+ rating and certified HVAC technicians.

Installation and Support Services by Cozy Comfort Plus

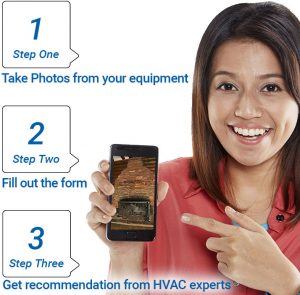

At Cozy Comfort Plus, we understand the importance of professional installation for your Carrier Weatherexpert 48N units. Our licensed HVAC technicians are ready to provide expert in-home evaluations, same-day quoting, and seamless installations for businesses in Toronto and the GTA. Need a repair or replacement? Our team is equipped to handle all service needs, ensuring your system operates at peak efficiency.

Visit Our North York Showroom for Demos and Consultations

Interested in seeing the Carrier Weatherexpert 48N in action? Visit our North York showroom for live demonstrations and personalized consultations. Our knowledgeable staff will guide you through the features, benefits, and financing options, including rental programs and potential rebates like the Canada Greener Homes Grant. Cozy Comfort Plus is committed to helping you find the best HVAC solutions for your commercial space.

Trust Cozy Comfort Plus for Your HVAC Needs

As a trusted provider of Carrier products in Toronto, Cozy Comfort Plus offers more than just installation. We provide comprehensive support, including repairs, maintenance, and troubleshooting. Explore our range of services and discover why we are a preferred choice for businesses across North York and the GTA. Contact us today for a quote or to learn more about our financing options and potential incentives.

Question 1: What is the price of Carrier Weatherexpert 48N Commercial Rooftop Units in Toronto?

Carrier Weatherexpert 48N prices vary based on configuration and installation needs. Contact Cozy Comfort Plus in Toronto for a detailed quote tailored to your commercial requirements.

Question 2: How efficient are the Carrier Weatherexpert 48N units?

The Carrier Weatherexpert 48N units are highly efficient, meeting or exceeding ASHRAE Standard 90.1 requirements. They feature multiple high-efficiency scroll compressors and advanced control systems for optimal energy savings.

Question 3: Can I get a rebate for purchasing Carrier Weatherexpert 48N in North York?

Yes, Cozy Comfort Plus can assist you with potential rebates such as the Canada Greener Homes Grant. While we help navigate these options, specific amounts and eligibility are subject to government guidelines.

Question 4: How does installation work for Carrier Weatherexpert 48N units?

Cozy Comfort Plus offers professional installation by certified HVAC technicians in Toronto and North York. We ensure seamless setup with minimal disruption to your business operations.

Question 5: What are the pros and cons of Carrier Weatherexpert 48N units?

Pros include high efficiency, advanced control systems, and robust construction. Cons can include initial investment costs. However, potential rebates and energy savings often offset these costs over time.

Question 6: What support services does Cozy Comfort Plus offer post-installation?

Cozy Comfort Plus provides comprehensive support, including regular maintenance, troubleshooting, and repair services for Carrier Weatherexpert 48N units in Toronto and the GTA. Our team ensures your system remains efficient and reliable.